Authors: Luka Čurović, Tadej Novaković, Pero Gatarić, Jurij Prezelj

Abstract: Tumble dryers are a common appliance in many households. Their energy efficiency has improved considerably with the introduction of a heat pump tumble dryer, but reducing noise emissions remains a difficult task for engineering departments. The objective of this paper is to develop an experimental acoustic analysis of a commercial heat pump tumble dryer. First, the main noise sources, including the BLDC motor, the centrifugal fan, the drain pump and the ventilation duct, were identified using various acoustic methods. Viscoelastic dumping and sound absorbing materials were then used to suppress emissions from the identified sources. Sound power level and directivity measurements were performed to evaluate the significance of the identified sources to the overall noise emission. The A-weighted sound power level was reduced from 64.8 to 60.4 dB and the directivity pattern was improved. In addition, annoyance and sound quality were assessed. In the end, we were able to reduce the (Zwicker-Fastl) psychoacoustic annoyance by 50% and improve the sound quality of the device by 2 classes. The proposed experimental approach for noise identification and validation approach can be applied to other complex household appliances of similar size.

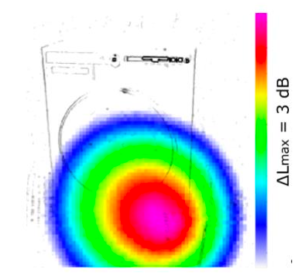

Acoustic image (front side)

Keywords: Domestic appliance, Noise reduction, Tumble dryer, Annoyance reduction